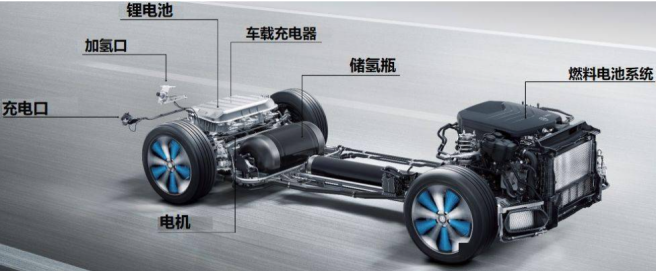

The role of thermistor temperature sensors in lithium-ion batteries for electric vehicles.

Using thermistor temperature sensors in rechargeable batteries ensures optimal performance and safety, providing stable temperature monitoring for battery packs and safeguarding operational security!

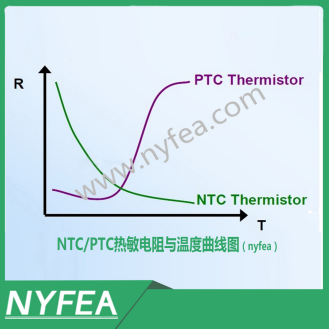

A Thermistor is a semiconductor component highly sensitive to temperature, classified into Positive Temperature Coefficient (PTC) thermistors and Negative Temperature Coefficient (NTC) thermistors.

NTC thermistors are used for temperature measurement, control, and compensation, functioning as temperature sensors.

PTC thermistors are used for temperature measurement and control, can also serve as heating elements, and simultaneously act as a "switch," integrating the three functions of sensing element, heater, and switch, hence referred to as a "thermal switch."

NTC thermistors exhibit Negative Temperature Coefficient, meaning their resistance decreases significantly as temperature increases. Utilizing this characteristic, NTC components are commonly used in small appliances for soft-start circuits, automatic detection, and control circuits.

PTC thermistors exhibit Positive Temperature Coefficient, meaning their resistance increases significantly as temperature rises. This property is often utilized in automatic control circuits.

Lithium-ion batteries are highly sensitive to overcharging. When charged beyond the safe voltage threshold, the risk of leakage, smoking, combustion, or rupture significantly increases, and such hazards can be severe. Overcharging may result from charging system malfunctions, electrode errors, or using incorrect chargers.

Purpose of Protection Circuits

These circuits monitor various parameters during battery charging and discharging to address potential faults, ensuring battery lifespan and efficiency while protecting both the battery and external devices from damage.

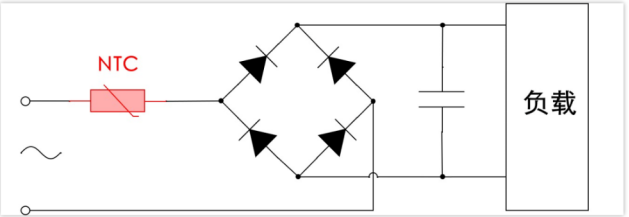

The primary functions of NTC thermistors in batteries include:

1. Ensuring the battery achieves its designed cycle life

2. Enabling more economical and efficient charging

3. Providing precise temperature measurement, which is crucial for displaying remaining battery runtime

△ Circuit Example of Secondary Battery and Charger Using NTC Thermistor for Temperature Detection

Batteries typically employ a primary protection circuit consisting of a battery protection IC and MOSFETs. The protection IC monitors battery voltage and discharge current to control the FET's switching, preventing overcharging, short circuits, over-discharging, and other faults.

Early battery designs used fuses or bimetallic strips as secondary protection against overcurrent, short circuits, and overtemperature. However, since battery overcurrent faults are often temporary and don't necessarily indicate permanent damage, the non-resettable nature of fuses increased quality assurance costs for manufacturers. While bimetallic strips can self-reset, their repeated cycling can lead to early fatigue, contact wear, and eventual welding, causing protection failure. Additionally, bimetallic strips are relatively large and heavy compared to the stringent size and weight requirements for portable devices.

Solutions to the Above Issues:

Overcharge Protection:

According to GB/T18287-2000 requirements for lithium-ion battery overcharge protection, testing was conducted under two conditions:

① Batteries without protection circuits;

② Batteries protected only with a dedicated PTC.

Monitoring battery voltage and surface temperature revealed that unprotected batteries reached temperatures up to 120°C during overcharging, eventually leading to leakage, fire, or explosion. In contrast, batteries equipped with PTC (silicon thermal linear resistors) maintained surface temperatures below 80°C.

Short Circuit Protection:

During external short circuits, battery current can exceed 15A, easily surpassing the极限 operating parameters of power MOSFETs. Additionally, the protection IC cannot maintain stable operation during short circuits. These issues result in inadequate short circuit protection.

PTC components provide protection before MOSFET failure, ensuring battery cycle life and reducing manufacturers' quality assurance costs.