The Application of Chip NTC Thermistors in 5G Electronic Equipment

A Thermistor is a semiconductor component highly sensitive to temperature, classified into Positive Temperature Coefficient (PTC) thermistors and Negative Temperature Coefficient (NTC) thermistors.

NTC thermistors are used for temperature measurement, control, and compensation, functioning as temperature sensors.

PTC thermistors are used for temperature measurement and control, can also serve as heating elements, and simultaneously act as a "switch," integrating the three functions of sensing element, heater, and switch, hence referred to as a "thermal switch."

NTC thermistors exhibit a Negative Temperature Coefficient, meaning their resistance decreases significantly as temperature increases. Utilizing this characteristic, NTC components are commonly used in small appliances for soft-start circuits, automatic detection, and control circuits.

PTC thermistors exhibit a Positive Temperature Coefficient, meaning their resistance increases significantly as temperature rises. This property is often utilized in automatic control circuits.

With the widespread adoption of 5G technology across various devices, the 5G era has truly arrived. Key differentiators of 5G compared to earlier 2G, 3G, and 4G mobile communications include:

1. Significant improvements in communication speed, data processing capacity, and connection capability to meet the demands of high-data-volume transmission (e.g., HD images, video, virtual reality) and real-time applications (e.g., autonomous driving, remote medicine, IoT communication);

2. Achievement of a user experience data rate of 100 Mbit/s under conditions of continuous wide-area coverage and high mobility.

3. Enhanced system coordination and intelligence, manifested as multi-user, multi-point, multi-antenna, multi-access coordinated networking, and flexible automatic adjustment between networks.

These characteristics increase the load on related components within 5G devices, consequently increasing heat sources. Multiple heat sources can also interact thermally. Measures previously effective for single heat sources may not suffice for simultaneously managing the thermal states of multiple functional hotspots in 5G electronic devices.

Based on this context, monitoring the temperature of multiple functional hotspots on the substrate and controlling the performance of components acting as heat sources according to the complex functions of the electronic device becomes particularly important.

For instance, when a CPU runs a demanding application, it may operate at full power initially while its temperature is low. If the CPU temperature rises, its performance might be throttled to prevent exceeding a critical threshold. If the power supply unit providing power to the CPU also generates significant heat, and this heat transfers to the CPU, the CPU's temperature could rise sharply. Considering the temperatures around both the CPU and the power IC simultaneously necessitates more granular control over each component's performance.

While implementing temperature control for components on the substrate, it is also crucial to note: since heating components continuously generate heat, ultimate overheating protection might be necessary – for example, displaying a warning or switching to a shutdown state.

The substrate design must account for the internal temperature of each heat source, IC, and module, as well as the heat exchange between them and temperature changes in the surrounding environment where the electronic device is placed. Only by monitoring the temperature around heat sources can the aforementioned temperature management be achieved.

NTC SMD thermistors, being suitable for surface mounting like other EIA size standard chip resistors, capacitors, and inductors, offer high configuration freedom, occupy minimal space, and can achieve desired accuracy with simple circuits. Therefore, NTC SMD thermistors are ideally suited as temperature sensors placed at specific measurement points on the substrate to enable temperature monitoring.

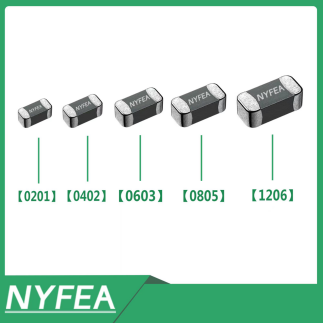

Figure 1. NTC SMD Thermistor Product Images

Furthermore, NTC SMD thermistor manufacturing processes are mature, allowing for short development cycles for new products and mass production of variants with different characteristics. Production capacity expansion and miniaturization can be achieved by adding corresponding equipment, facilitating cost reduction.

NTC SMD Thermistor Detection Circuit

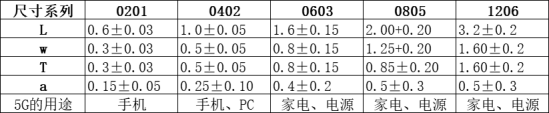

The diagram below shows an example of a temperature detection circuit utilizing an NTC SMD thermistor.

Figure 2. Example of an NTC SMD Thermistor Temperature Detection Circuit

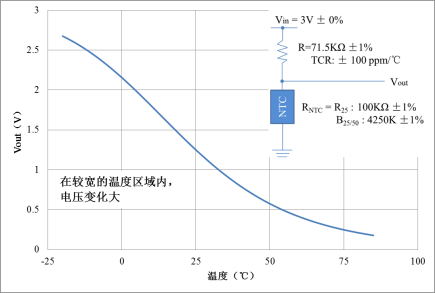

The NTC SMD thermistor is connected in series with a chip resistor, and a constant voltage is applied. The relationship between the resulting divided voltage and the temperature of the NTC SMD thermistor is shown in Figure 3.

Figure 3. Temperature Characteristic of the Divided Voltage (Vout)

A very large voltage change can be obtained over a wide temperature range. This voltage change is processed as temperature information, allowing warnings to be issued when the temperature exceeds a set threshold.

It is noteworthy that although the voltage change in Figure 2 is significant, no amplifier is used before the Analog-to-Digital Converter (ADC). Unlike many sensors used in electronic devices, whose signals are often very weak and require amplification, the NTC SMD thermistor is one of the few sensors that typically does not require an amplifier.

Let's consider the ADC resolution. Assuming, as in Figure 2, that the voltage applied to the NTC SMD thermistor circuit is the same as the reference voltage for the ADC within the microcontroller, and the ADC input range is 0V to 3V. If the ADC resolution is 10 bits, the quantization step size (LSB: Least Significant Bit) becomes approximately 3 mV.

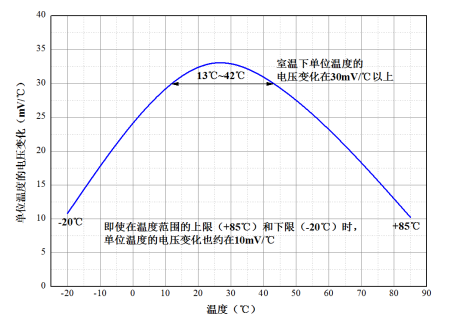

Furthermore, the voltage change per degree Celsius (gain) achievable over the same temperature range as Figure 3, i.e., -20°C to +85°C, is shown in Figure 4. Even at the upper and lower limits of the temperature range where the gain is smallest, a gain of about 10 mV/°C is obtained. At this point, 1 LSB corresponds to about 0.3°C. Thus, a temperature resolution of about 0.3°C can be expected even with a standard 10-bit ADC integrated into a microcontroller. Of course, around room temperature, the gain exceeds 30 mV/°C, making 1 LSB equivalent to less than 0.1°C.

Figure 4. Voltage Change per Degree Celsius (Gain)

Using a standard ADC found in microcontrollers, a temperature detection circuit can be easily implemented with a simple design. This is a primary reason why NTC SMD thermistors are widely used for temperature detection in electronic devices.

Simple Circuit & High-Accuracy Temperature Measurement

So, what level of temperature measurement accuracy can be achieved using standard NTC SMD thermistors and resistors?

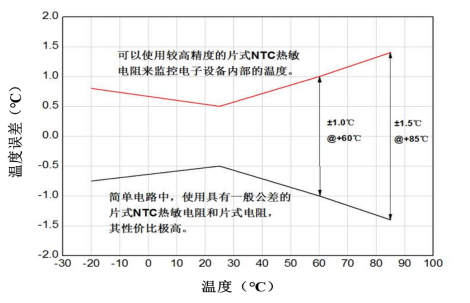

Refer back to Figure 3. This chart shows the voltage-temperature characteristic when using an NTC SMD thermistor and a chip resistor, both with a resistance tolerance of ±1%. It plots the central value of the obtained voltage and the upper/lower limits calculated based on the maximum component tolerances. The differences are almost negligible. Figure 5 converts these upper and lower limit deviations from the central value into temperature error.

Figure 5. Vout Error from Figure 3 Converted to Temperature

The results show an error of approximately ±1°C at +60°C and about ±1.5°C at +85°C. For monitoring temperatures inside electronic devices, such as substrate temperature, this represents sufficiently reliable measurement accuracy.

High-accuracy temperature measurement can be achieved using simple components and circuits, making the high cost-effectiveness of NTC SMD thermistors self-evident.

NYFEA possesses an advanced NTC SMD thermistor production platform with a mature and flexible formulation system. This enables the rapid development of new specifications, high-precision, and highly reliable quality products tailored to customer needs, assisting electronic devices in the 5G era to accurately monitor temperature.