Smart Manufacturing

We will continuously surpass ourselves, persist in independent innovation, and provide customers with more professional services

Quality positions include IQC, IPQC, OQC, QA, strictly implementing quality inspection work according to the factory's quality management system documents. Relying on high-precision testing equipment to reduce production quality abnormalities.

The certification supervision department reviews corresponding documents to evaluate suppliers' quality control capabilities, product stability, and engineering R&D capabilities, requiring them to provide necessary supplementary materials. After passing the production feasibility assessment and signing the sample approval letter, they can be approved as new suppliers.

![]()

![]()

![]()

With core technical support from upstream partners such as chip manufacturers, cloud service providers, and intelligent algorithm companies, we possess resources and leading advantages for integrated innovative development, enabling faster synchronization to solve problems encountered during smart hardware R&D and production processes, helping customers address pain points, providing one-stop audio-video intelligent software and hardware customized ODM services, including ID design, UI design, APP design, embedded software development, cloud technology development, intelligent algorithms, electronic circuit design, structural design, testing and verification, supply chain management, production manufacturing, quality assurance, and other one-stop design, R&D, and production services.

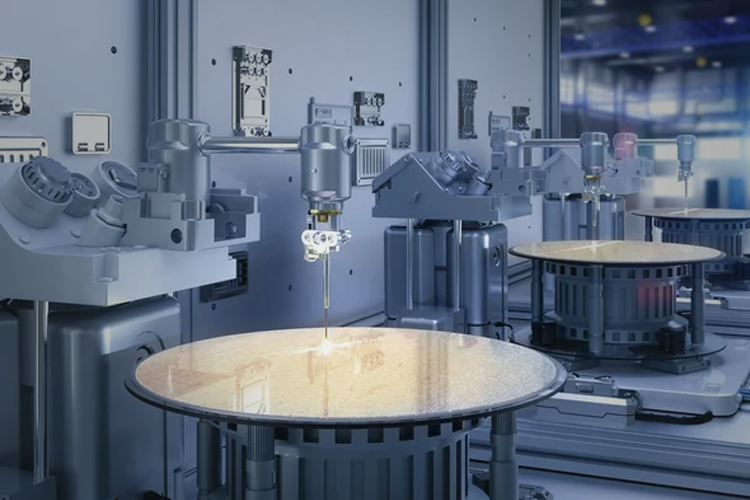

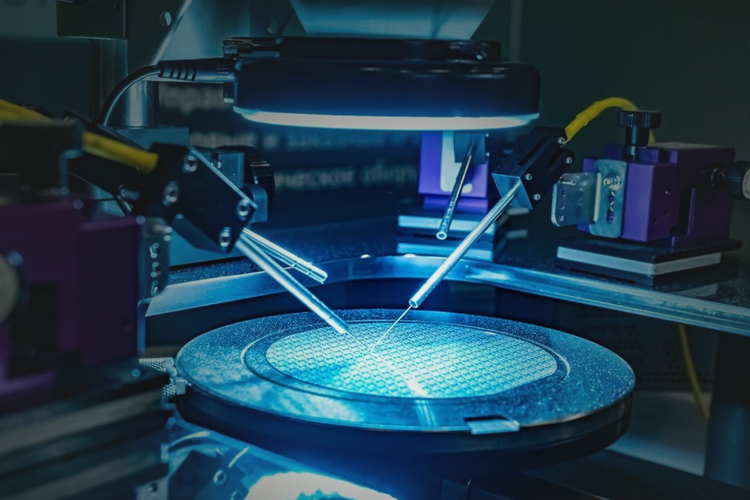

The company continuously invests in equipment automation transformation projects, focusing on independent R&D of automation equipment, significantly improving production automation levels, continuously shaping new momentum and advantages for development with "hardcore" strength, introducing high-end GDM300 DFG8560 grinding and cutting equipment, with grinding capacity of 600 pieces per day, DFD6361 cutting equipment.